Engineering Excellence That Keeps You Moving

Services

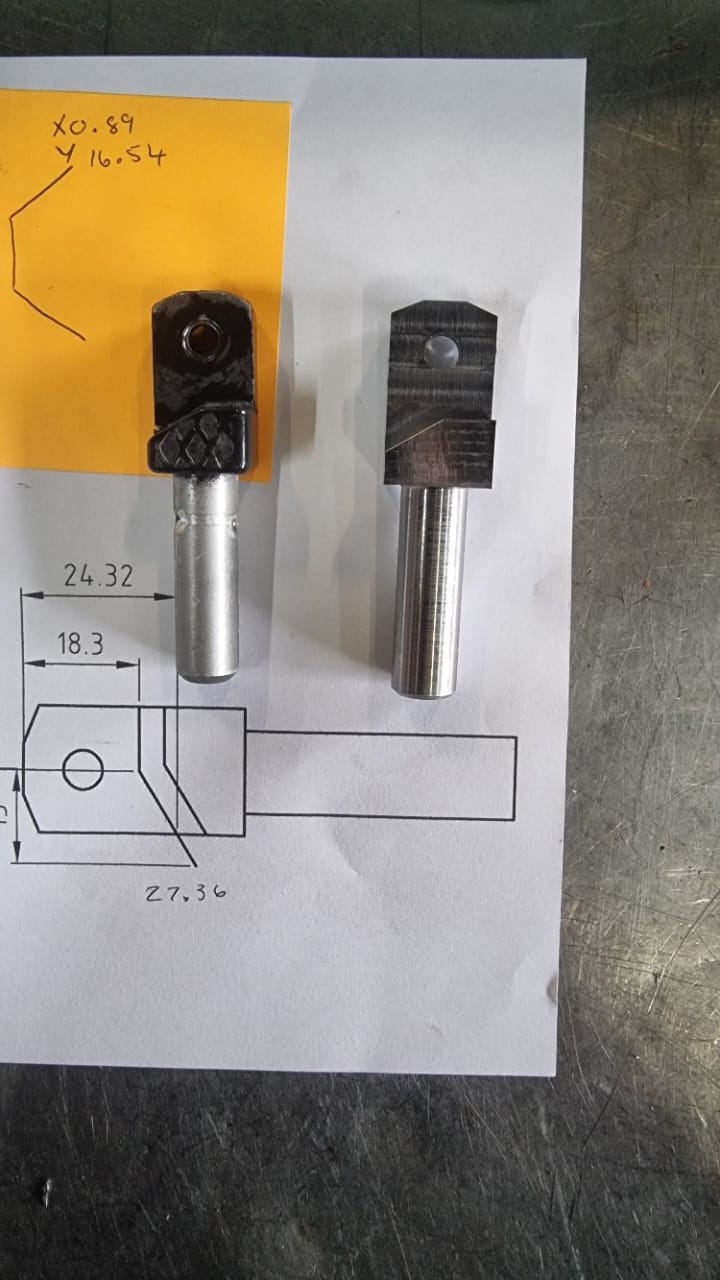

Advanced CNC Machining

At Kimmins Engineering Services (KES), our CNC machining division is equipped to deliver high-precision components tailored to exacting client specifications. Utilizing state-of-the-art CNC lathes and a high-performance milling machine, we consistently produce components with tight tolerances, complex geometries, and high repeatability — essential for demanding industrial applications.

Whether it’s a once-off prototype or high-volume production, our skilled machinists and engineers work closely with clients to ensure every part meets rigorous quality standards. We machine a variety of metals and engineering plastics, catering to sectors such as mining, manufacturing, automotive, and hydraulics.

🔧 Our capabilities include:

Turning, milling, drilling, and threading

Precision part replication from technical drawings or samples

Machining of both standard and custom-designed components

Fast turnaround times for urgent and planned jobs

With a strong emphasis on performance, accuracy, and reliability, our CNC machining services support your operations by delivering parts that work the first time, every time.

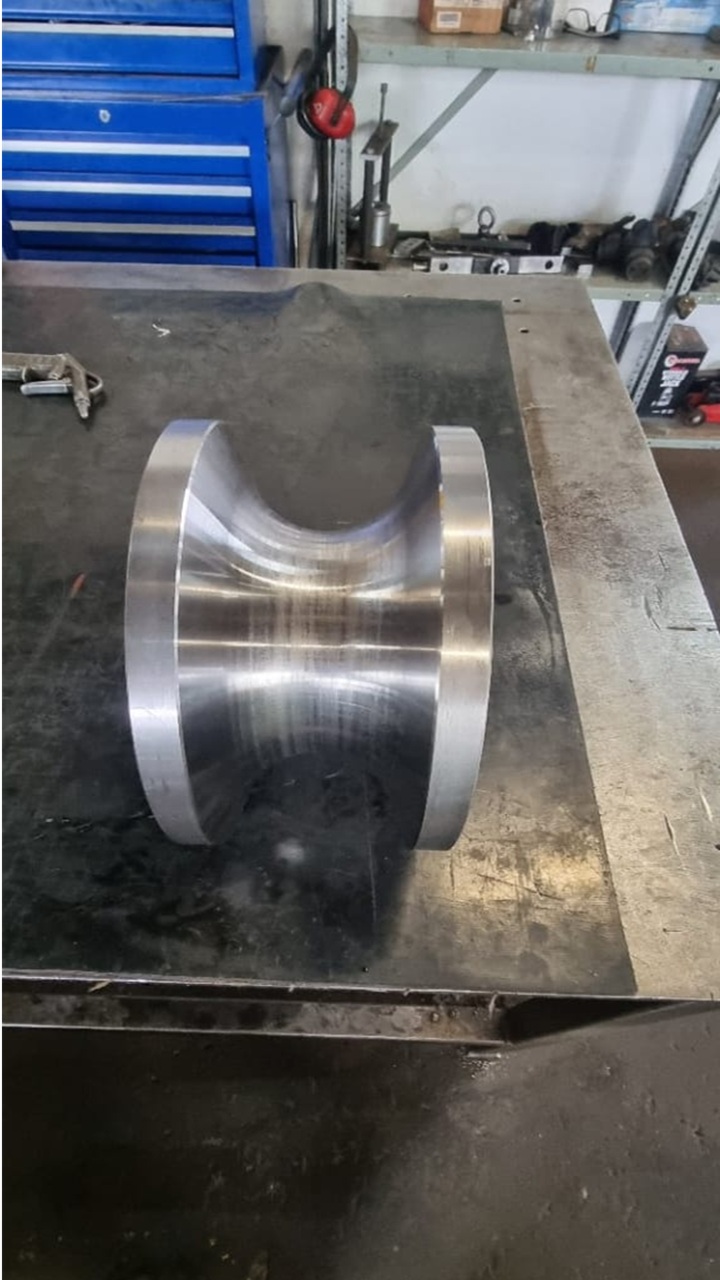

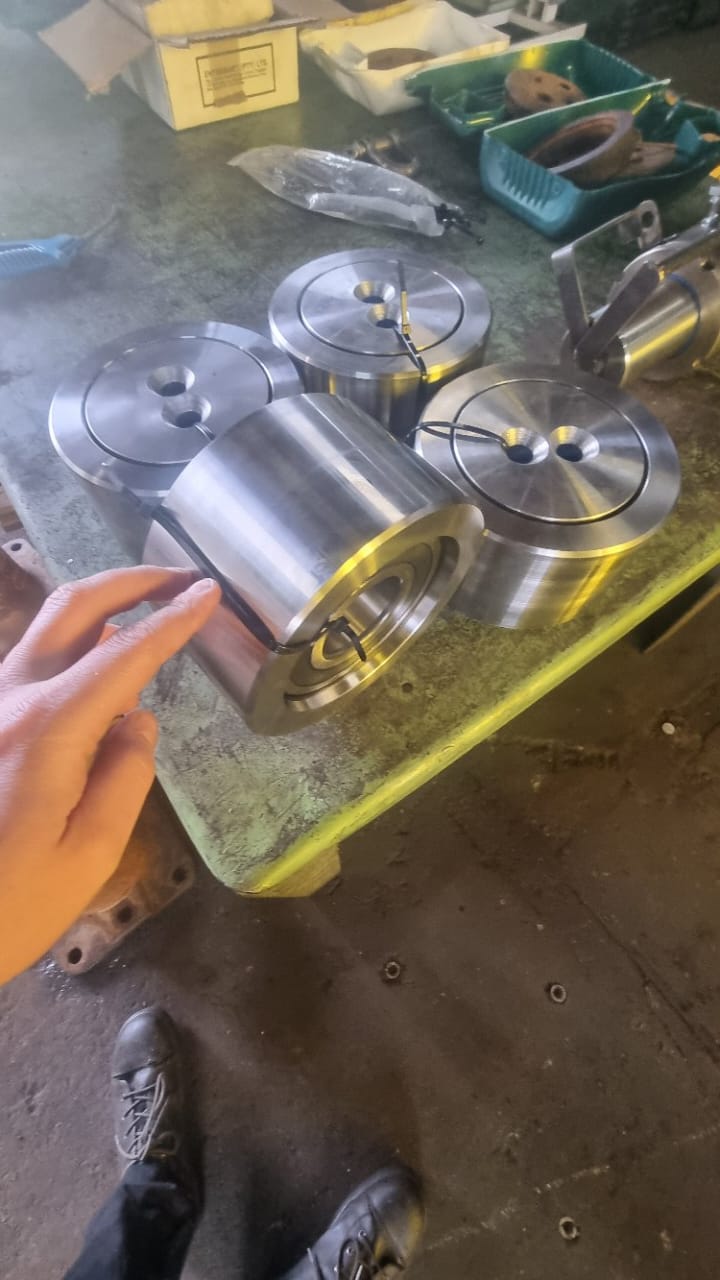

Hydraulic Solutions

At Kimmins Engineering Services (KES), we offer end-to-end hydraulic services that support a wide range of industrial applications. From routine maintenance to complex system repairs and component supply, we are trusted by industries that depend on performance, safety, and reliability.

Our team specializes in the repair, refurbishment, and custom manufacturing of hydraulic cylinders, valves, power packs, buffers, and other critical hydraulic components. With a deep understanding of hydraulic principles and system dynamics, we diagnose faults quickly and deliver solutions that restore full functionality — minimizing your operational downtime.

💡 Our hydraulic capabilities include:

Repair and reconditioning of single- and double-acting cylinders

Supply and integration of hydraulic valves, hoses, seals, and fittings

Custom-built power packs designed to meet site-specific demands

Testing and pressure calibration to ensure optimal performance

On-site inspection and support services for urgent interventions

Whether you’re dealing with worn components, high-pressure leaks, or system inefficiencies, KES delivers expert hydraulic engineering that keeps your equipment operating safely and efficiently.

Fabrication & Welding

At Kimmins Engineering Services (KES), we deliver high-quality fabrication and welding solutions designed to meet the demands of industrial environments. Our fully equipped workshop enables us to handle everything from precision light fabrication to robust heavy-duty structural work.

Our fabrication services are backed by expert welders and machinists, capable of working with a wide range of materials including mild steel, stainless steel, and aluminium. Using advanced equipment — including two 500Amp welding machines, a TIG welder, hydraulic presses, and conventional milling and lathes — we produce durable, accurate, and cost-effective parts and structures to spec.

🧰 Capabilities include:

TIG, MIG, and MMA welding

Fabrication of machine parts, brackets, frames, and enclosures

Repair and reinforcement of worn or damaged components

Pressing, bending, and assembly of custom parts

In-house design consultation and prototype development

Whether you’re building from blueprint or modifying existing equipment, KES ensures weld integrity, dimensional accuracy, and fast turnaround times — helping you reduce downtime and improve reliability in the field.

LOCK N LOAD Systems

⛓️ LOCK N LOAD Conveyance Chairing Systems

At Kimmins Engineering Services (KES), we are proud suppliers of the industry-trusted LOCK N LOAD Conveyance Chairing Systems — engineered for maximum safety, reliability, and efficiency in shaft operations.

Designed specifically for the mining sector, this system offers controlled conveyance stability during loading and unloading, significantly reducing the risk of sudden movement and improving overall operational safety underground.

⚙️ How It Works:

Once the conveyance is positioned, the LOCK N LOAD system connects to a high-flow air supply via a quick coupler. The system’s air/oil pump builds pressure and automatically stalls at the desired clamp force, thanks to its balanced piston design, ensuring pressure is maintained.

When loading or unloading is completed:

The air supply is removed

A controlled decompression cycle is activated through an electro/proportional relief valve and air release valves

Clamping pressure is released gradually, allowing the conveyance to move smoothly and safely in either direction, depending on the load change

🔒 Key Benefits:

Reduces risk of dangerous shaft movement

Ensures safer loading and unloading

Automatically maintains pressure without active monitoring

Trusted and used by leading mining operations

As a trusted provider of the LOCK N LOAD system, KES ensures expert support, system integration, and servicing to help our clients maintain the highest safety standards in their underground operations.

About Us

At Kimmins Enginnering Services (KES), we specialize in precision mechanical engineering and manufacturing services, catering to a wide range of industrial sectors. With a strong focus on quality and performance, we offer CNC machining, fabrication, hydraulic system solutions, and custom component manufacturing. Our workshop is equipped with advanced CNC lathes, milling machines, and state-of-the-art welding and pressing equipment to ensure reliable results and fast turnaround times. We are also proud suppliers of the LOCK N LOAD Conveyance Chairing Systems, trusted by leading mining operations for their safety and durability. Whether it’s supplying valves, repairing hydraulic cylinders, or fabricating bespoke parts, we deliver engineering excellence that keeps your operations moving.

Gallery